Since 2000, the world has doubled its coal-fired power capacity after explosive growth in China and India. Higher capacity power stations are being built and planned. Most of the system architecture in those power plants is based on single-wire data transmission. Any failure of the data collection that happens in the device unit or the network will cause transmission failure, which will impact the operations and maintenance practices of power plant performance. The objective of this case is to assess best practices for retransforming the environmental protection data transmission system through the LoRaWAN® network, conducting temperature monitoring for equipment, and strengthening the environmental monitoring frameworks of coal-fired power plants.

Challenges

Some of the challenges they are facing currently when they don't have smart monitoring solutions are because there's not any real-time data collection availability. There are not as many streamlined reporting systems that can accurately process real-time data collection happening all around as you have imagined. And basically, they want to be able to make a fast response based on the real-time data they might not be able to handle with the current infrastructure.

Predictive maintenance and machine health check-ups:

-

-

- Monitor coal conveyor belt, pulverizer, coal storage, workshop

- Vibration, speed, noise and dust, temperature monitoring and heat, toxic gases

- Power failure monitoring

- Manage field equipment and operations

-

Implementation problems:

-

-

- Devices are located in harsh environments with scarce connectivity

- Access to data and real-time alerts and insights

- Rising costs of maintenance and labor

- Legacy Equipment- Sensor provisioning

- Data normalization

-

Project

Thermal energy in Asia remains a major electricity source, with coal-fired power plants in China alone generating almost 75% of electricity. Coal-fired power plants in China are expected to continue to account for the majority of the country’s electricity till 2030.

Solution

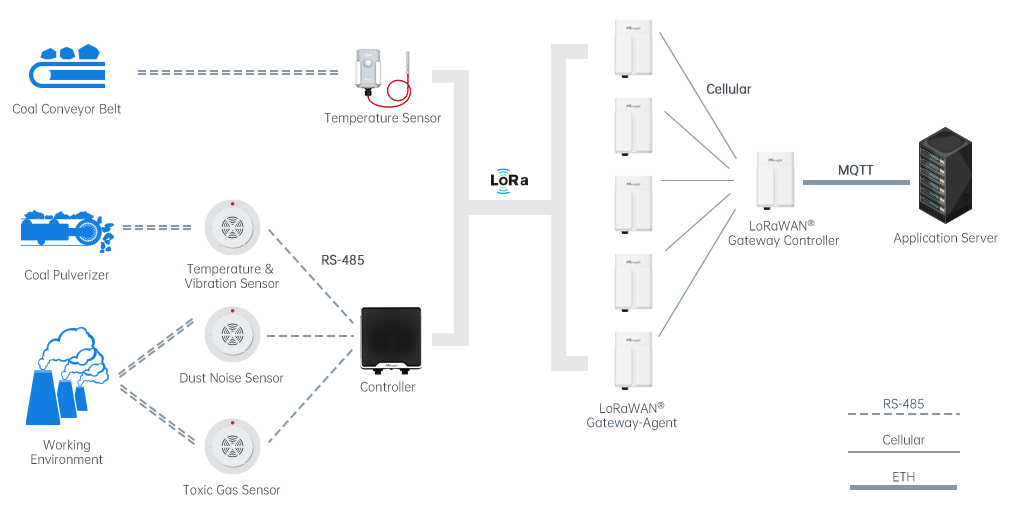

What we are starting to see is that that kind of anchor project for our networks is one of the industrial segments that in general from temperature monitoring to vibration and air quality measurement. But the first couple of projects dated all the way back in 2019 were actually around the offset and displacement of boilers. In this project, we deployed the wide-range temperature monitoring sensors, controllers, and gateways to build up a basic infrastructure that leveraging the LoRaWAN® technology for long-range communication, from which we were turning expertise in the power plant segment and able to demonstrate the smart industry solution with the power of the LoRa technology.

Overall the requirements from the coal-fired power plant authorities are the wishes to integrate their legacy sensors into the LoRaWAN® network and automate their data reading and transmission works which include the ability to monitor temperature, dust, noise, and vibration of equipment to measure the toxic gases emission and also to determine whether any situation arises against the threshold settings. By understanding what the environment looks like in the workshop at the industrial level and being able to get real-time monitoring availability throughout that entire process, admins will become more responsive to the management of different situations.

Once the LoRaWAN® gateway receives the data from the sensors, it’s processed by the gateway embedded network server directly and then forwarded by MQTT to the cloud where the monitoring center is hosted by the customer himself.

The continuous monitoring data can be generated in a unified form in a log or report for all the staff day-by-day work.

Featured Products

Featured Products

Deployment

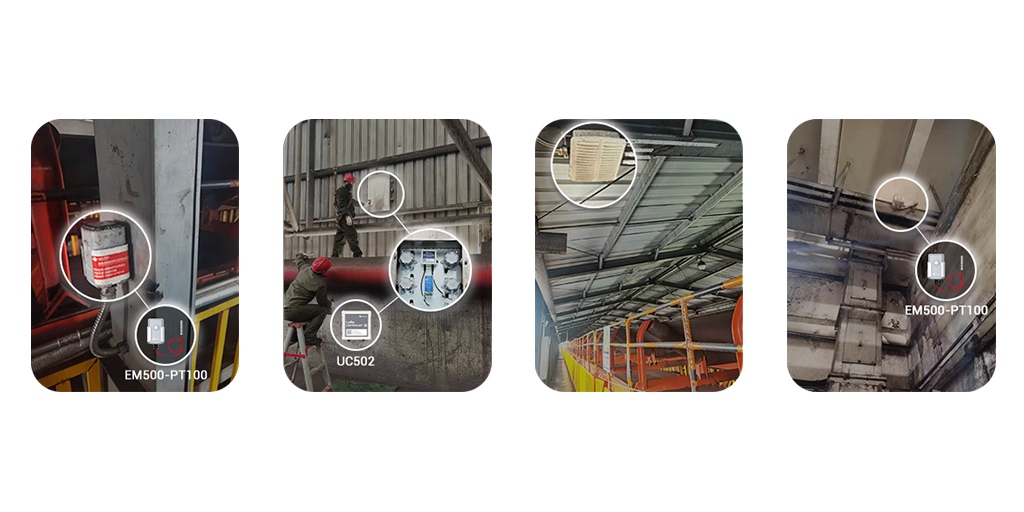

Currently, 30 units of LoRaWAN® temperature sensors, 20 units of controllers, and 6 units of outdoor LoRaWAN® gateways from Milesight are already installed throughout the power plant. They are communicating seamlessly and no packet loss or loss of services to date as part of this project.

The existing legacy sensors are saved to connect with the LoRaWAN® network through the RS-485 interface of controllers, which not only satisfies the investment requirement but also simplifies the installation.

The industrial design of the EM500-PT100 can be easily fastened on the belt to monitor the temperature and forward data to the UG67 gateway wirelessly through LoRa. By enabling the “noise analyzer” function of the gateway to determine the best signal strength, engineers can pinpoint the best position to install the sensors and gateways before real installation.

As multiple gateways are required to cover the whole area in the plant, with the “gateway fleet” function, the private network is rolled out efficiently at scale. One unit is configured as the controller gateway and the rest units as agent gateways that purely work as a forwarder. All the data is going to be aggregated in the controller gateway via the cellular network and processed by the embedded network server, and it will transmit to the customer's applications server through an Ethernet port via MQTT protocol.

Benefits

Increase data accuracy, operational and management efficiencies.

- Reduction in operating cost by receiving timely information

- Low power consumption supported by low-cost sensors

- Low infrastructure cost of a wireless and private network

- Improved employee satisfaction index and safety

- Help in quick emergency response

- Receive alerts if data is against threshold setting

About Guodian Suqian Power Plant

In 2015, the Jiangsu Provincial Development and Reform Commission approved the new coal-fired power generation project of Guodian Suqian. The construction included two units of 660MW ultra-supercritical secondary reheating equipment and related supporting facilities.